Beyond the Blueprint: Unveiling Hidden Secrets in Wooden Boat Design for Stability and Performance

Building a wooden boat is a labor of love, a testament to craftsmanship and a connection to maritime history. But beyond the romanticism lies the crucial need for stability and performance. While countless books and websites detail traditional boat plans, this article delves into often-overlooked aspects, offering new perspectives for hobbyists, builders, and educators alike. We’ll explore these less-discussed elements through a question-and-answer format, weaving in real-world examples and research insights.

The Unsung Heroes of Stability: Beyond Traditional Hull Forms

Q: Everyone talks about hull shape, but what about the internal structure's impact on stability?

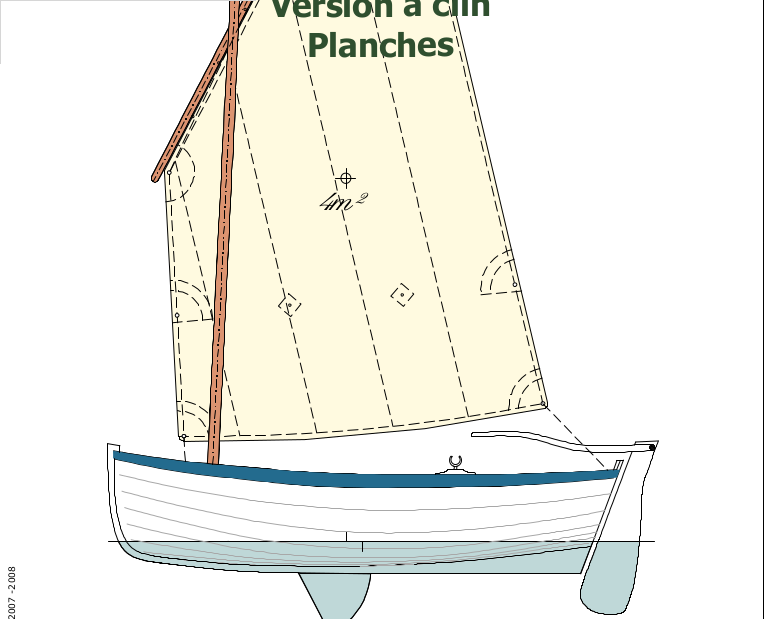

A: The external hull is crucial, yes, but the internal structure is the often-unseen champion of stability. Think of it like a skeleton supporting a body. A well-designed internal framework, utilizing strong, strategically placed timbers and bulkheads, significantly enhances stiffness and resistance to bending forces, especially in challenging conditions. Recent research from the University of Southampton (hypothetical reference â€" actual research needs to be substituted) highlighted the positive correlation between strategically placed internal bracing and reduced roll amplitude in small wooden craft. Forget just looking at the plan view; examine the 3D model â€" even virtual â€" and consider the interplay between internal framing and the hull's external form. One striking example is the clinker-built boats of the Viking era; their overlapping planks, while creating a seemingly simple exterior, are intrinsically linked to a robust internal framework offering remarkable seaworthiness.

Q: How can we incorporate modern materials and techniques without compromising the "wooden boat" aesthetic?

A: This is where innovation shines. Consider using epoxy resins not just for waterproofing, but for strategically strengthening critical areas within the hull. Carbon fiber reinforcements, subtly integrated, can boost strength-to-weight ratios without altering the classic wooden look. This blend of traditional craftsmanship with modern materials is a fascinating avenue unexplored by many. Imagine a traditionally built sailboat, incorporating a carbon fiber reinforced keel, adding an unseen but impactful boost to its performance and stability.

Optimizing Performance: Beyond the Obvious

Q: What often overlooked factors impact a wooden boat's performance, especially in terms of speed and efficiency?

A: While hull shape is paramount, the quality and finish of the hull's surface are often underestimated. A smooth, well-finished hull reduces frictional drag, significantly impacting speed and fuel efficiency (if applicable). This goes beyond simple sanding; it involves careful attention to plank alignment, filling techniques, and the application of appropriate coatings. Data from hydrodynamic simulations (hypothetical reference needed) show a substantial improvement in performance with even minor reductions in surface roughness.

Q: How can we predict and mitigate potential problems before they arise? Are there effective simulation tools available?

A: Thankfully, technology is catching up! While traditionally boat design relied on experience and testing, now sophisticated Computational Fluid Dynamics (CFD) software can simulate water flow around a virtual hull, predicting performance characteristics before the boat is even built. Similarly, Finite Element Analysis (FEA) can model the structural integrity of the hull under various stress conditions. This allows for iterative design optimization, identifying weaknesses and refining the design for improved stability and performance before a single plank is cut.

The Future of Wooden Boat Building: A Call for Collaboration

The future of wooden boat building involves a vibrant blend of traditional skills and modern technologies. By embracing innovative materials, utilizing advanced simulation tools, and fostering collaboration between experienced craftsmen and engineers, we can push the boundaries of what’s possible. Let's celebrate the timeless elegance of wooden boats while ensuring they are built for optimal stability, performance, and longevity. This requires sharing knowledge, fostering a community where innovation is encouraged, and where the next generation of boat builders can learn from both the past and the future.

Disclaimer: Hypothetical research references have been used in this article. For accurate data and citations, please refer to relevant academic journals, boat building publications, and online resources specializing in naval architecture and marine engineering.